I. Overview:

The KL 2.5L V6 is part of the Mazda K series V6 DOHC EFI engines. There are 2 basic versions: the KLDE and the KLZE. The KLDE [KLD, KL03], is the low compression version at 9.2:1, with mild cams and oval port heads and intake runners. The KLZE is higher compression at 10:1, longer duration/higher lift cams, and has big square runners and ports. Here is a good comparison of the KLZE and KLDE intake runner size.

At 84.5mm x 74.2mm, it is a very short stroke motor. With a 138.35mm rod c/c length, that makes for a 1.86:1 rod ratio. That is very high for a street driven production motor. This high rod ratio would lend itself to being a very high revving motor, but the KL is not in stock form. Why? Well the mild cam specs in stock form do not help. The intake valves are 32mm each, so that is not the issue, they just don't stay open enough.

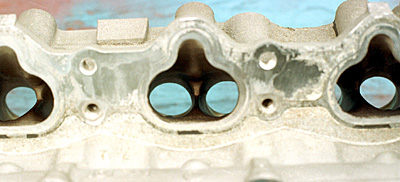

KLDE combustion chamber:

KLDE intake ports:

KLDE exhaust ports:

KLDE versus KLZE intake runner size/shape:

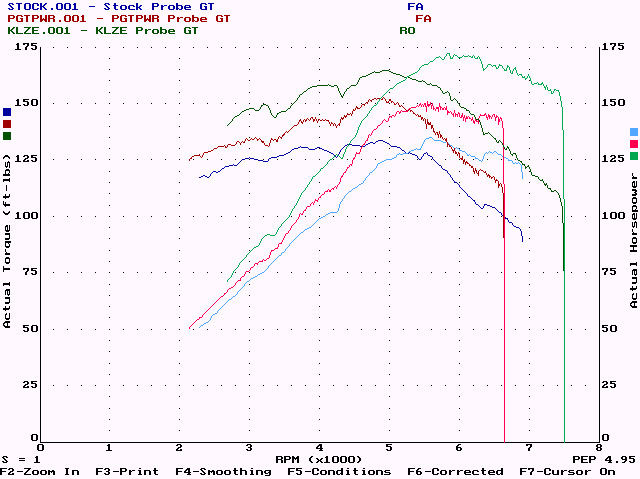

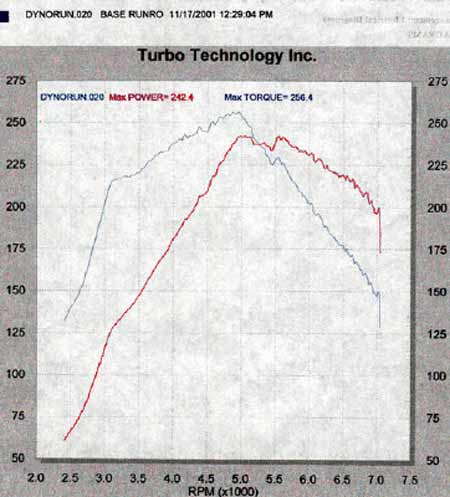

The Blue curve is a stock KLDE in a Probe GT MTX [135whp @

5600RPM, 134 ft lbs @ 4800RPM].

The Blue curve is a stock KLDE in a Probe GT MTX [135whp @

5600RPM, 134 ft lbs @ 4800RPM].

The Red curve is

a KLDE with headers, intake, and exhaust [151whp @ 5600RPM, 152 ft lbs @

4900RPM].

The Green curve is a KLZE running an

ECU from a KLDE; very different VRIS poitns as shown by the dips in the curves @

the KLDE VRIS points [172whp @ 5900RPM, 160 ft lbs @ 5000RPM].

A) Cam specs:

The KLDE cam specs:

Intake opens at 8

degrees BTDC

Intake closes at 47 degrees ABDC

Exhaust opens at 50

degrees BBDC

Exhaust closes at 5 degrees ATDC

These values(above) are

mazda's.

KLDE cams and KLZE cams have the same cam profile for intake and

exhaust.

KLDE cams have 244deg. @ 0.004", 196deg @ 0.050", 67deg @ 0.300".

Max. lift is 0.338"

KLZE cams have 246deg @ 0.004", 200deg @ 0.050", 84deg @

0.300". Max lift is 0.350".

B) Valve specs:

Exhaust valve size = 27.7-28.0mm

Intake valve size = 32.0 mm

C) Valvespring

rates:

Rod Weight

Piston Weight

II. Limitations:

A) Normally Aspirated:

As previously stated, the first hurdle to jump when tuning a normally aspirated KL is the cams. The KLZE cams offer more duration, but are still OEM cams, and therefore mild. Interprep has done some R&D with KL cam designs through their Motorola Cup MX-6 experience in the late 90's. Alistair Oag is the man you want to talk to there. Colt Cams have also made regrinds. I have not heard any real results with these cams. They are located in Canada.

Another limitation is the stock airflow meter. Known as the VAF, it meters air by measuring the resistance across a potentiometer attached to a big cone in the intake path. This is quite restrictive, which is likely one of the reasons why most OEM's now use MAF sensors that restrict much less while also measuring mass instead of volume. Mike P and Andrew Brownsword have both successfully ditched the stock VAF for a high flowing MAF in KLDE cars. Another option to get rid of the VAF is to go to a MAP sensor with a speed density EFI system. Simple Digitial Systems, aka SDS, produce a low budget no frills stand alone EFI system which uses a MAP sensor. I have seen good results from this system in Jay B's 428whp 2.0L FE3 Turbo MX-6. It is incredibly simple to tune.

The only person I know of and have good information on that has experience with NA KL tuning is Steve "Tekguy". His KLDE rolled 176whp when he had it, and has since rolled 196whp in a new car with some new tweaks. Before he switched to an Acura RSX, I got his image archive, available here.

Interprep's Motorola Cup KLDE:

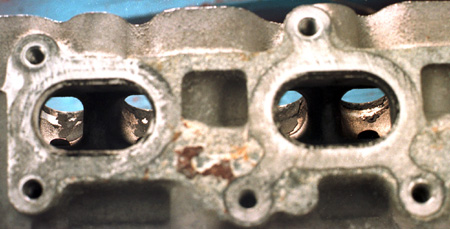

KLDE ports, taken out to near KLZE size. Note the rounded D-shape of the ports

Seat and bowl work on the heads.

Nice organized assembly process for rebuilding the head. Definitely the way to go [after having my K8DE heads in a card board box and all the retainers rolling all over creation...]

Another good view of the head, being prepped.

Head, waiting for HLA's and Cams.

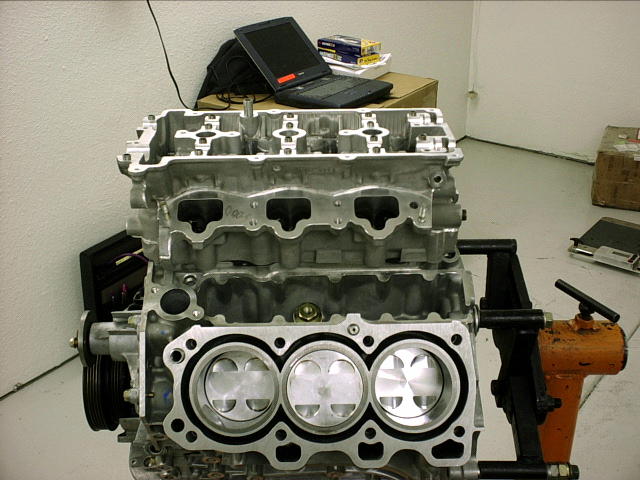

The block, with just the tensioner and water pump in place.

Nice aftermarket pistons and rods to stand up to high RPM Normally Aspirated abuse on the track.

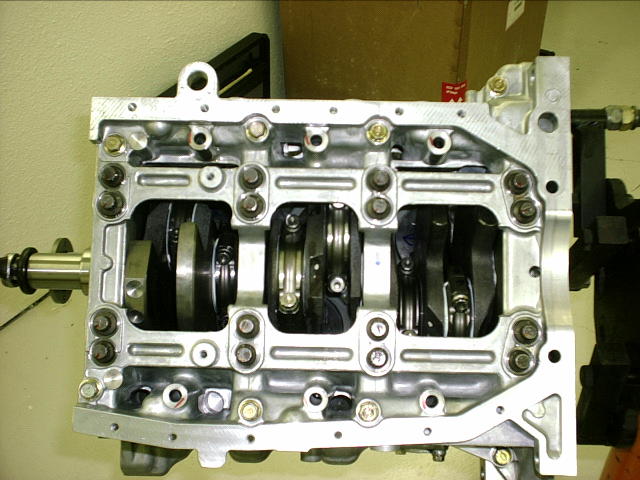

Great shot of the 4 bolt mains. I guess it's a 4 bolt, even though it's really a whole girdle due to the split block design, so it doesnt really have the traditional bearing caps. You can really see the Porsche engineers' influence here.

Short block, with both block halves in place, complete rotating assembly, sans the oil pump though.

The back side of the engine. Sorta like the front side, but different.

The engine coming together, with rear head on and awaiting lifters and cams.

Another view.

Both heads and valvetrains in place. The rear cam sproket is a 5 spoke design, which I have never seen elsewhere on other K series motors. Though it doesnt look custom...might be a slick way to get some more flexibility on cam timing within Motorola cup rules...You can also see the larger water pump shaft diameter is used here.

Timing the motor, and apparently checking valve lift at certain crank positions as well.

B) Forced Induction:

The KL has a forged crank, split crankcase, oil squirters, oil tap plugged on the block, and block girdle stock. It is definately ready for forced induction. The first limitation you will run into with your basic SC/TC system is fuel. Running a larger fuel pump and a rising rate FPR [FMU], you will get to the where the stock 190-220cc/min injectors start to have spray patterns [fuel pressures around 80-90psi] when you run around 6-8psi. Andrew Brownsword ran out of fuel @ ~5psi with his non intercooled KLDE on a T04E 50 trim. Chad from MIPOC and Alan Wong both have run upwards of 13psi on a stock block, but Alan had additional TB injectors whereas Chad was still on stock fuel. So for all intents and purposes, you need to upgrade fuel before you think about going internal, as nobody has blown an engine due to anything but running lean yet. You can get larger injectors from a few sources. Rafi at rr-racing.com has apparently convinced venom to make larger injectors using our stock, pain in the butt side feed injectors. Stock Millenia S injectors pre 99 are 280cc/min. Stock Millenia S injectors 99+ are 305cc/min. Stock secondary injectors from a 13B-REW from a FD3S are 850cc/min, and drop in the stock rails. These would support upwards of 900bhp. Joe Kamman has successfully modified two SR20DE rails to fit a KL. They have 259cc/min injectors stock, and he has upgraded those units to 370's. Should be enough fuel for his monster Eaton M90 PGT project. Getting them to idle below 2000RPM would be quite a fun trick, but probably doable with a stand alone EFI system. The plus about stand alones is that you also control spark timing, which adds to your margin of safety under boost. *UPDATE* June 2002- Joe has gotten his 370's to run with a TEC2. Check the Forced Induction forum on Probetalk.com for more info [username Joe Kamman]

The next issue you're going to want to address is your stock cast rods and pistons. Yeah, they have lasted over 12psi, but probably by the grace of God. Some good forged units would definately put my heart at ease approaching 1bar. Victor Pavlovets has put together a forged bottom end kit for the KL:

Hey guys, a friend of mine who is building my current engine, is interested in putting together a piston + rods kit. This will be a true fit kit so you won't need to do any work like the TKT kit. Here is what he wants to include

Eagle H-beam rods (much stronger than I-beam rods)

Wiseco Pistons,

pins, rings, clips

Rod bearings

Main bearings

Thrust Washers

Machined Crank.

You can get the pistons in any size and any CR you want. The whole

rotating assembly will be completely balanced. All you would have to do is have

the block bored out by a local shop if you’re going with bigger bore pistons,

unlike the TKT kit which you have to do a ton of machine work to make the parts

fit together. I just got off the phone with him and he said that price wise were

looking at about $2200.

*update*$1600 for H beam Rods, Wiseco Pistons, pins,

rings, clips

*update*$1690 same as above plus, rod and main bearings and

thrust washers.

Let me know what you guys think. PM me or email me at

vicpgt@rogers.com if you’re interested.

Thanks

Victor Pavlovets

After you've upgraded your fueling [and controlling it] and your bottom end, nobody knows what the limit is. The standard headwork would be a good idea [port and polish, solid lifters, high lift cams with low overlap, bigger ports, bigger valves, etc]. The highest HP KL's that I've heard of were 480bhp out of the stock 2.5L of displacement, but funny enough they were the normally aspirated IMSA motors. Of course at this point if you're using a piggyback system to control your injectors, I'd highly recommend a stand alone engine management system. SDS, Electromotive , Haltech, Motec, Fel-Pro, and DFI all make good systems with various features that may be necessary for your application. I personally like the SDS as it has a higher resolution than many systems and is incredibly to tune quickly and get running on the street without days on the dyno.

Also, the KLDE is 9.2:1, which is going to be more turbo friendly on pump gas. The KLZE has 10:1 static compression, which, while being lower than all B-series VTEC motors, will be more prone to preignition than the KLDE. Sean Matthews has run 7-8 on his KLZE with a TD06 16G. If he were to get more fueling through either larger injectors or TB injectors, it would be very interesting to see how he could do on 8-10psi on 93 octane. I am no expert in the dark art of thermodynamics, but it seems that there is a good amount of quench and squish area on the head, so pump gas [94 octane] should be good to over 10psi. But again, nobody has blown up any KL due to anything but lean-out detonation, so the preignition limit of the KL is also unknown.

You'll note that most of this section refers to turbos and not superchargers. That's because I dislike ineffeciency, and therefore superchargers. If you have a supercharger, I don't hate you. Rather, you're just misguided :) Howard Chu made an awesome excel spreadsheet specifically for a KL turbocharged setup.

KLDE @ ~8psi [T3 Super 60 compressor, large Spearco FMIC, 255LPH inline pump,

and FMU]:

1: Manny's turbo Setup

2G PGT MTX, T04E 60 trim compressor, T3 turbine, hotshot primaries, FMU, Spearco FMIC, low boost.

Early pictures of test fitting.

Yes, you can squeeze a T04E compressor there.

Unlike most KL turbo setups, Manny was able to keep his cross member unhacked or modified. Note the huge T04E compressor.

Nice Spearco FMIC.

The backside of the IC. Still some room, but it's getting tight.

Blitz BOV on the nice aluminized hardlines for the cool side of the turbo piping. I'm not sure if he got those with the little lip on them so the hoses don't pop off under boost though [highly recommended].

Using the Hotshot primaries, an equal length secondary system was developed. It sort of follows the stock design, in a round about manner.

A good view of the pipe going into the turbine [top of picture] and down pipe [bottom of picture].

A good overview out of car of the hot side piping.

The hot side piping after being coated.

All the piping in the car, wrapped, clamped, and ready for action.

Big compressor and low boost means alot of vented exhaust gasses, so a big TIAL is in place.

2: Sean Matthew's Turbo setup

1992 Mazda MX-3 GSR, KLZE [KL31 cams, Curved Eunos manifold, etc], K8 VAF & ECU, Mitstsubishi 16G [big or small?], FMU, Starion FMIC, all home made. Ran 13.78 @ 108 on 17" street tires, very traction limited [couldn't launch hard due to frequently broken axles]. Sean has run 6-7psi daily driven on 92 octane with no octane boosters with no problems for over a year now. So for all you ZE turbo naysayers...here it is:

Locating the compressor where the battery used to reside, that provides more flexibility on downpipe size and shape than Manny's setup. Makes the intake piping creative though...

Using the stock collectors, Sean just made the pipes come right together and then feed into the turbo [2" to 2.5" I believe], to minimize thermal lag and help spool.

Another angle, Note the big downpipe.

Later on Sean welded on a small dump tube for the wastegate I believe.

Note: Thanks to Michel Fortier for some of the great KLDE and KLZE engine pics. The SAE paper was originally converted by Howard Chu and Mike P. The cam specs were graciously provided by Mike Seli. Manny took his own turbo setup pics. Sean's pics were jacked from his constantly down or moving website[ ;-) ]